After a 27-year wait marked by numerous legal and political challenges, the Republic of Guinea is poised to launch a $20 billion iron ore, rail and port development this year.

Expected to become the world’s largest and highest-grade new iron ore mine, the project will contribute approximately 5% to the global seaborne supply upon commencement.

The initiative traces its roots back to 1997 when Rio Tinto secured a license to explore the mountain’s iron ore. Over the years, Guinea endured two coups d’état, witnessed four heads of state, and held three presidential elections.

In 2024, Rio Tinto aims to kickstart this ambitious project once its state-owned Chinese partners receive the final approval from Beijing, marking a significant milestone for the Anglo-Australian miner in undertaking its most intricate venture to date.

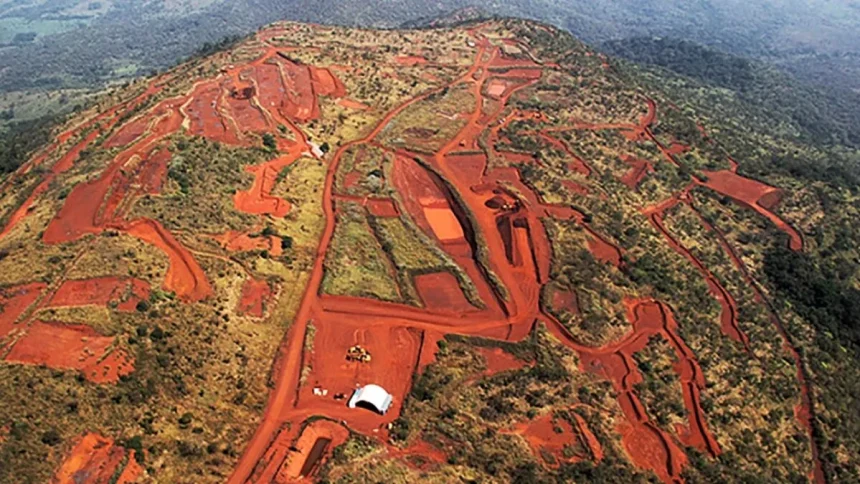

Simandou’s Mining Project

At the heart of this venture lie the Simandou mountains. Having secured the exploration rights in 1997, Rio Tinto will now see construction begin, following anticipated investment approvals from Beijing for the state-owned Chinese partner, Chinalco. The project comprises two iron mines, a 400-mile rail system, and a port in proximity to Guinea’s capital, Conakry.

The project is a collaboration involving Rio Tinto, the Guinean government, and at least seven other companies.

Rio Tinto is set to construct the Simfer iron ore mine in collaboration with a consortium led by Chinalco, the world’s largest aluminium producer.

Additionally, the WCS iron ore project will be developed by Baowu, the world’s largest steel producer, in partnership with a consortium led by Singapore-based Winning International Group.

Both parties will co-finance the construction of a 552km railway and a deepwater port on Guinea’s Atlantic coast, and an additional 70km rail spur to connect its mine with the main line. Rio Tinto Group will spend around $6.2 billion on the development of the project.

Decarbonising The Industry

To cut emissions, the industry is exploring alternative approaches, such as direct reduced iron technology in which the ore is treated using hydrogen and carbon monoxide, rather than coke.

Such processes require high-grade iron ore, which is increasingly hard to find in large quantities.

The ore Rio Tinto plans to extract from Simandou has an average iron content of greater than 65 per cent, among the highest in the world. Baatar calls it the “caviar of iron ore”.

Baatar stressed that Simandou has the potential to help decarbonise the Chinese steel industry.

“The only way the steelmaking industry globally decarbonises is if China decarbonises,” he added.

In 2022, China produced 1bn tonnes of steel, representing more than half of global production.